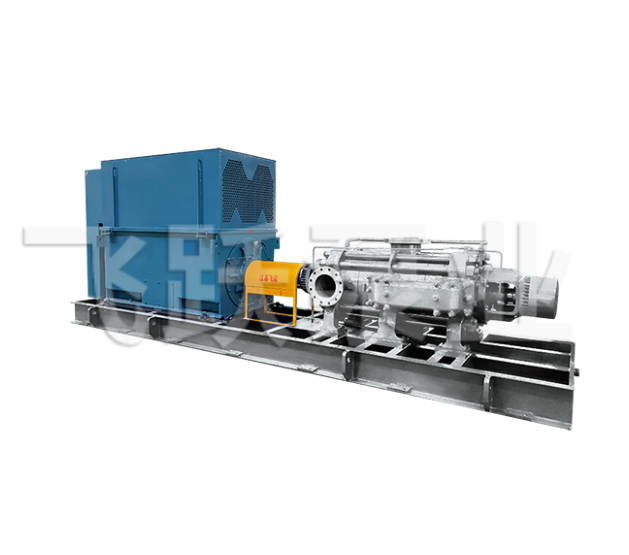

Wear-resistant multistage pump

A wear-resistant multistage pump is a centrifugal pump that increases the pressure of the fluid step by step through a series combination of multiple impellers and guide vanes…

A wear-resistant multistage pump is engineered to deliver high lift and stable pressure output through a series of impellers and diffusers arranged in multiple stages. Each stage incrementally elevates fluid pressure, enabling long-distance and high-head transportation. Its most defining feature is its exceptional abrasion resistance, achieved through enhanced materials, reinforced fluid channels, and optimized hydraulic geometry.

This pump category is widely selected by industries handling abrasive liquids, sand-laden water, slurry mixtures, and corrosive suspensions.

Key Advantages of Wear-Resistant Multistage Pump Technology

High-Durability Pump Structure

The wear-resistant multistage pump adopts elevated structural rigidity. Key components—such as impellers, casings, and wear rings—are constructed with high-hardness alloys or coated with ceramic composites. This ensures extended service life even under continuous contact with solid particles.

Enhanced Abrasion and Impact Resistance

The hydraulic passage is optimized to reduce turbulence and minimize particle collision. Surface hardening processes greatly reduce erosion rates, allowing the pump to maintain clearance accuracy and hydraulic efficiency over prolonged cycles.

Stable Performance in High-Lift Applications

Thanks to the multistage configuration, the pump delivers consistent pressure output, making it suitable for high-head systems in mining drainage, chemical recovery lines, municipal pressurization stations, and power plant auxiliary systems.

Reliable Operation and Reduced Maintenance

The combination of anti-wear materials, balanced rotor design, and precise sealing systems reduces unscheduled shutdowns. Users benefit from fewer component replacements, lower maintenance costs, and stable operation under demanding conditions.

Customizable Options from a Wear-Resistant Multistage Pumps Provider

As an experienced wear-resistant multistage pumps provider, manufacturers can tailor materials, stage numbers, shaft seals, bearing arrangements, and coatings to meet site-specific requirements.

Manufacturing and Processing Techniques for Wear-Resistant Multistage Pump Components

Material Selection for Maximum Longevity

Critical components utilize materials such as:

-

High-chromium cast iron

-

Duplex stainless steel

-

Ceramics or carbide-coated steels

-

Polymer reinforced liners (for specific chemical environments)

These materials offer superior hardness, erosion resistance, and corrosion tolerance.

Precision Machining and Surface Treatment

Advanced CNC machining ensures dimensional accuracy of wear rings, impeller vanes, and diffusers. Surface finishing techniques—including thermal spraying, bead blasting, and chemical passivation—further improve smoothness and extend operational lifespan.

Balanced Rotational Dynamics

Multi-stage rotors are dynamically balanced to minimize vibration and wear on bearings and seals. This contributes to stable, quiet, and energy-efficient performance even under fluctuating loads.

Quality Assurance and Performance Testing

Each pump undergoes hydraulic testing, pressure evaluation, and material hardness inspection. These procedures ensure compliance with international pump standards and verify long-term resistance to abrasive media.

Application Fields of Wear-Resistant Multistage Pump System

Mining and Mineral Processing

The pump is widely used for mine drainage, tailings transport, sand-water mixtures, and recovery systems requiring high lift and heavy-duty abrasion resistance.

Power Generation Industry

Power plants rely on these pumps for ash handling, desulfurization systems, and high-pressure auxiliary water circulation that contains solid impurities.

Chemical and Petrochemical Processing

In chemical environments, the pump handles corrosive liquids with suspended particles, meeting both abrasion and corrosion resistance requirements.

Municipal Water Engineering

Municipalities deploy these pumps for long-distance water delivery, river water lifting, and sewage treatment processes where solids and sediment are present.

Industrial Production Lines

Manufacturing sectors use these pumps for process water circulation, abrasive wastewater transfer, and media filtration systems.

Comparison with Conventional Pump Types

Wear-Resistant Multistage Pump vs. Standard Multistage Pump

A standard multistage pump is suitable for clean water or liquids with minimal suspended particles. In contrast, a wear-resistant version is designed for abrasive media and offers:

-

Higher material hardness

-

Better resistance to erosion

-

Longer service life in particle-laden flows

-

More stable efficiency retention over time

Wear-Resistant Multistage Pump vs. Slurry Pump

Slurry pumps excel at handling high concentrations of solids but usually operate at lower pressures.

Wear-resistant multistage pumps provide:

-

Higher lift and pressure output

-

Better suitability for long-distance transmission

-

More efficient operation in medium-abrasive, high-head environments

When to Choose Each Type

Choose a slurry pump for high-density slurry and short-distance transfer.

Choose a wear-resistant multistage pump when both abrasion resistance and high-pressure output are required simultaneously.

How Wear-Resistant Multistage Pumps Supplier Supports System Optimization

A specialized wear-resistant multistage pumps supplier provides engineering guidance, selection support, customization services, and operational assistance. Their expertise ensures:

-

Correct material configuration

-

Proper stage design

-

Efficient matching with pipelines, valves, and control systems

-

Long-term reliability with minimized operating expenses

FAQ

1. What media can a wear-resistant multistage pump handle?

It can transport slurry, sand-laden water, muddy fluids, industrial wastewater with particles, chemical liquids with abrasives, and other erosive media.

2. What materials are available for the impeller and casing?

Common choices include high-chromium cast iron, duplex stainless steel, bronze alloys, and wear-resistant composites. Selection depends on particle hardness, corrosiveness, and operating temperature.

3. How long is the typical service life of wear components?

Wear life varies based on particle size, flow velocity, and operating hours. With proper material configuration and coating, service life can be significantly longer than that of standard pumps.

4. Are these pumps suitable for continuous operation?

Yes. They are specifically built for continuous duty in harsh environments and maintain stable performance under sustained high-pressure loads.

5. Can the pump be customized for non-standard conditions?

Absolutely. Stage numbers, coatings, seals, shaft materials, and bearing types can be tailored to meet temperature, chemical, or abrasion requirements.

6. What is the recommended maintenance cycle?

Regular inspection of wear rings, impellers, bearings, and seals should be performed based on operating intensity. Predictive monitoring is recommended for large-scale or critical installations.

7. How does particle size affect the pump’s service life?

Larger, harder particles increase erosion rates. Hydraulic design and material choice help minimize the negative impact, but operating conditions should always be evaluated during pump selection

Reviews

There are no reviews yet.