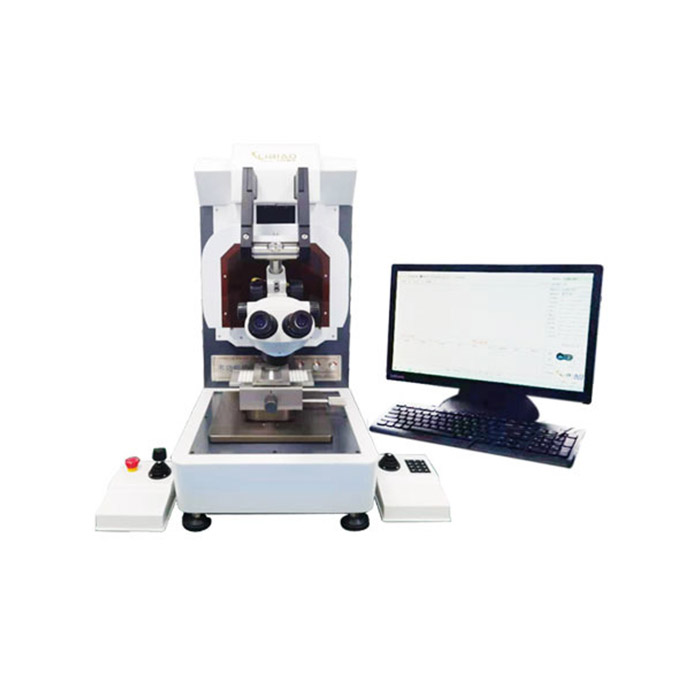

LB-8600 Multi-function Automatic Bond

The system is compatible with both domestic and imported optical components, including bright field, dark field, differential interference contrast (DIC), polarization, and epi-fluorescence options.

Basic Information

|

Product Model |

LB-8600 |

|

MOQ |

1 set |

|

Payment Terms |

T/T |

|

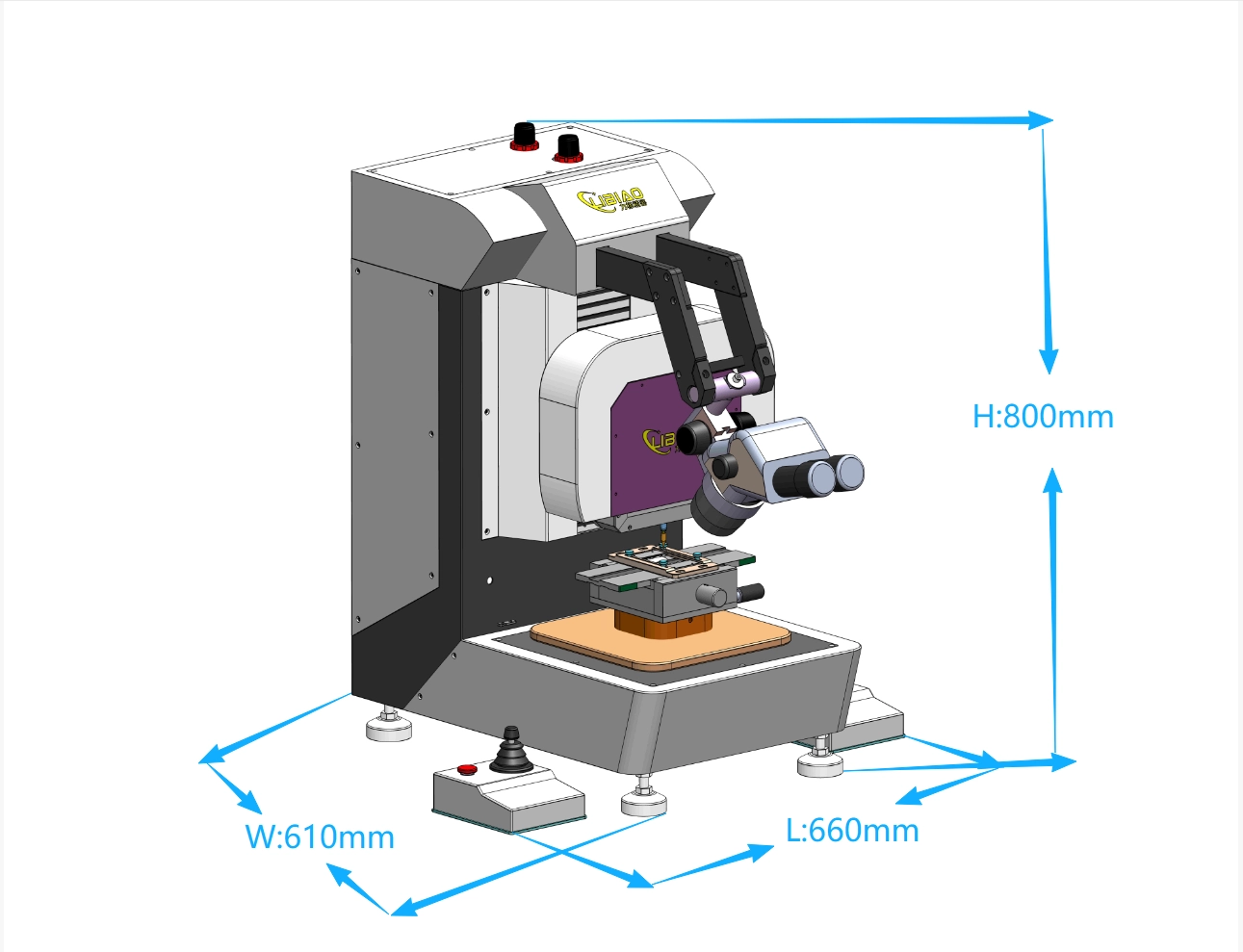

Footprint |

L: 660mm W: 610mm H: 800mm (both two joysticks included) |

|

Delivery Time |

Standard products are delivered within 25 days, excluding customized products. |

|

Transport Package |

Wooden Case |

|

Customized Service |

Support (Color, Logo, Test Fixture,Module,etc) |

|

HS Code |

44031644Q9 |

|

International Certification |

ISO9001 |

|

Service Process |

Provide one-stop pre-sales,in-sales services, after-sales training, ensuring worry-free use for customers. |

|

Technical Support |

Provide online support and technical consultation. |

|

Sample Policy |

Free sample testing. |

|

After-Sales Support |

1-year warranty period, supporting parts replacement and repair. |

|

Production Capacity |

200 PCS/ Year pcs/ Year |

Product Dimension Diagram

Equipment characteristics

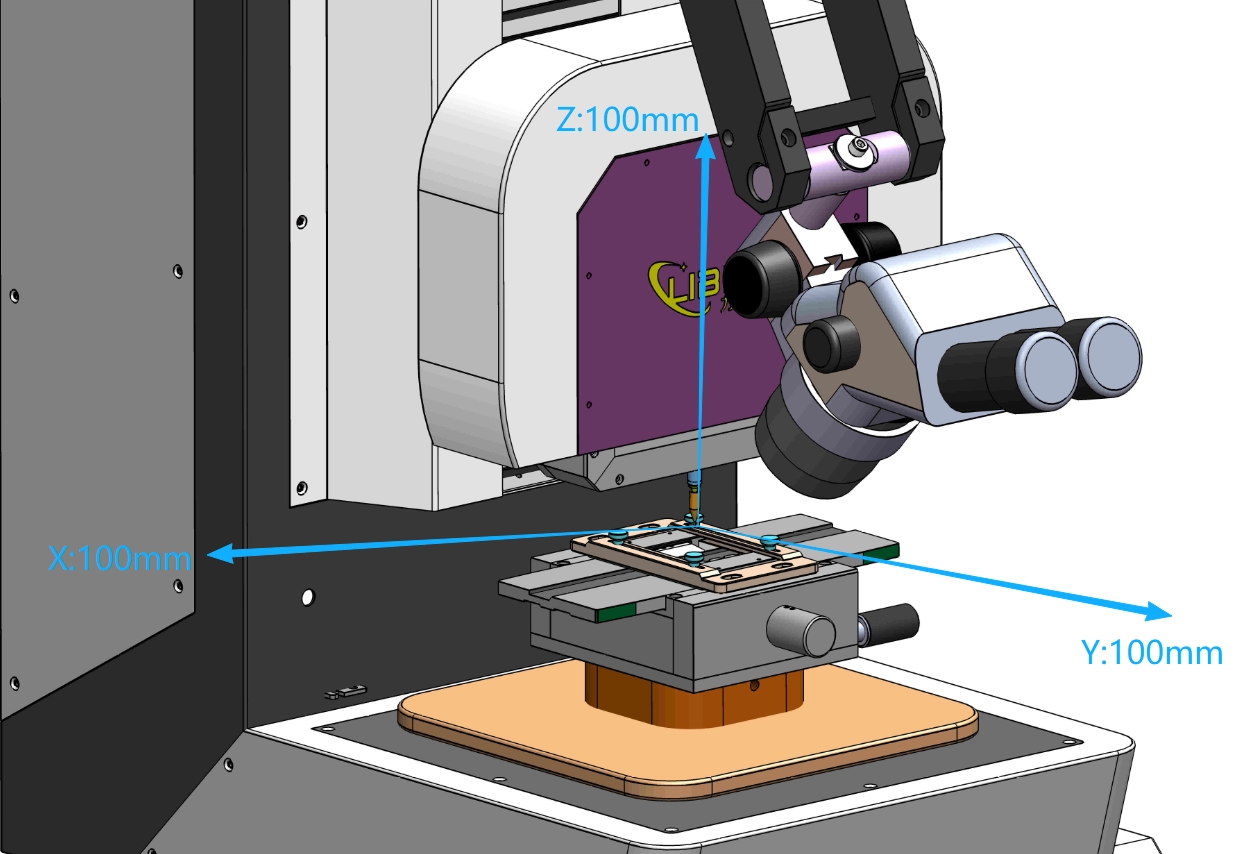

1. The device features a five-axis positioning control system with 100mm travel on the X, Y, and Z axes.

2. It has an ergonomic design and all-around protective measures, making operation simpler and more convenient.

3. The left and right Hall effect joysticks control the free movement of the XYZ platform.

4. The robust structure supports up to 200KG, with a maximum test force of 100KG on the Y-axis and 20KG on the Z-axis.

5. The intelligent automatic module exchange system reduces manual module replacement and improves testing efficiency.

6. High-precision dynamic sensors combined with unique mechanical algorithms ensure accurate testing in various environments.

7. The smart LED lighting system automatically turns off when idle and activates during use.

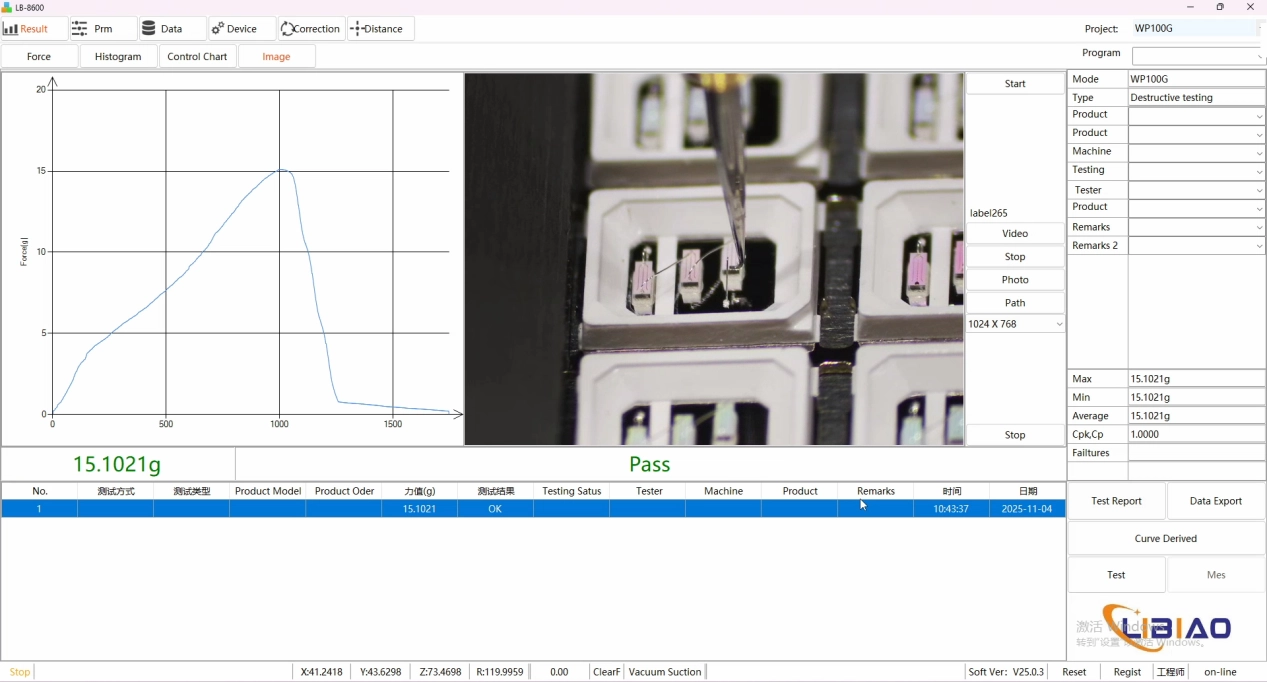

8. The bilingual software interface (Chinese and English) features customizable multi-level user access control.

9. The software allows selection of force units (Kg, g, N) according to testing needs.

10. Real-time test results, including histograms, force curves, and data export, are available, with MES system integration and SPC data export for max, min, average values, and CPK calculations.

Testing page

Testing Parameters

|

External Dimensions |

660mm×610mm×800mm (Including operation handrails) |

|

Weight |

Approx. 95KG |

|

Power Supply |

110V/220V; @0.30A; 50/60Hz |

|

Pneumatic Supply |

4.5-6 Bar |

|

Control Computer |

Intel / Windows10 PC |

|

Operating System |

Windows10/ Windows11 (with optional trinocular microscope& CCD high-definition camera) |

|

Test Mode |

Automatic (automatic measurement when the test item is in place, responds to sensor feedback to perform the test) |

|

Platform Leveling Accuracy |

360 degrees, can be adjusted to each platform |

|

XY Axis Effective Travel |

100 mm*100 mm,and can vacuum platform can be extended to 200mm x 200 mm, with a maximum test load of 200 KG |

|

XY Axis Moving Speed |

Uses precision XY table with independent control, maximum movement speed of 6 mm/S |

|

XY Axis Repetition Accuracy |

Repeatability ±5μm, movement accuracy ≤0.125mm, with precision ≤2μm |

|

Z Axis Effective Travel |

100mm,with a maximum test load of 20KG |

|

Z Axis Vertical Moving Speed |

Uses precision Z-axis control, maximum speed of 8 mm/S |

|

Z Axis Repetition Accuracy |

Repeatability ±2μm, travel within ±1μm |

|

Test Accuracy |

The equipment can test with 0.003%, accuracy of ±0.025% per tested part |

|

Calibration |

The equipment needs regular calibration (provided with standard calibration kit) |

|

Quality Assurance |

The device comes with a 1-year warranty, including hardware and software upgrades (not covering human damage) |

Diagram illustrating the effective travel of the X,Y and Z Axis

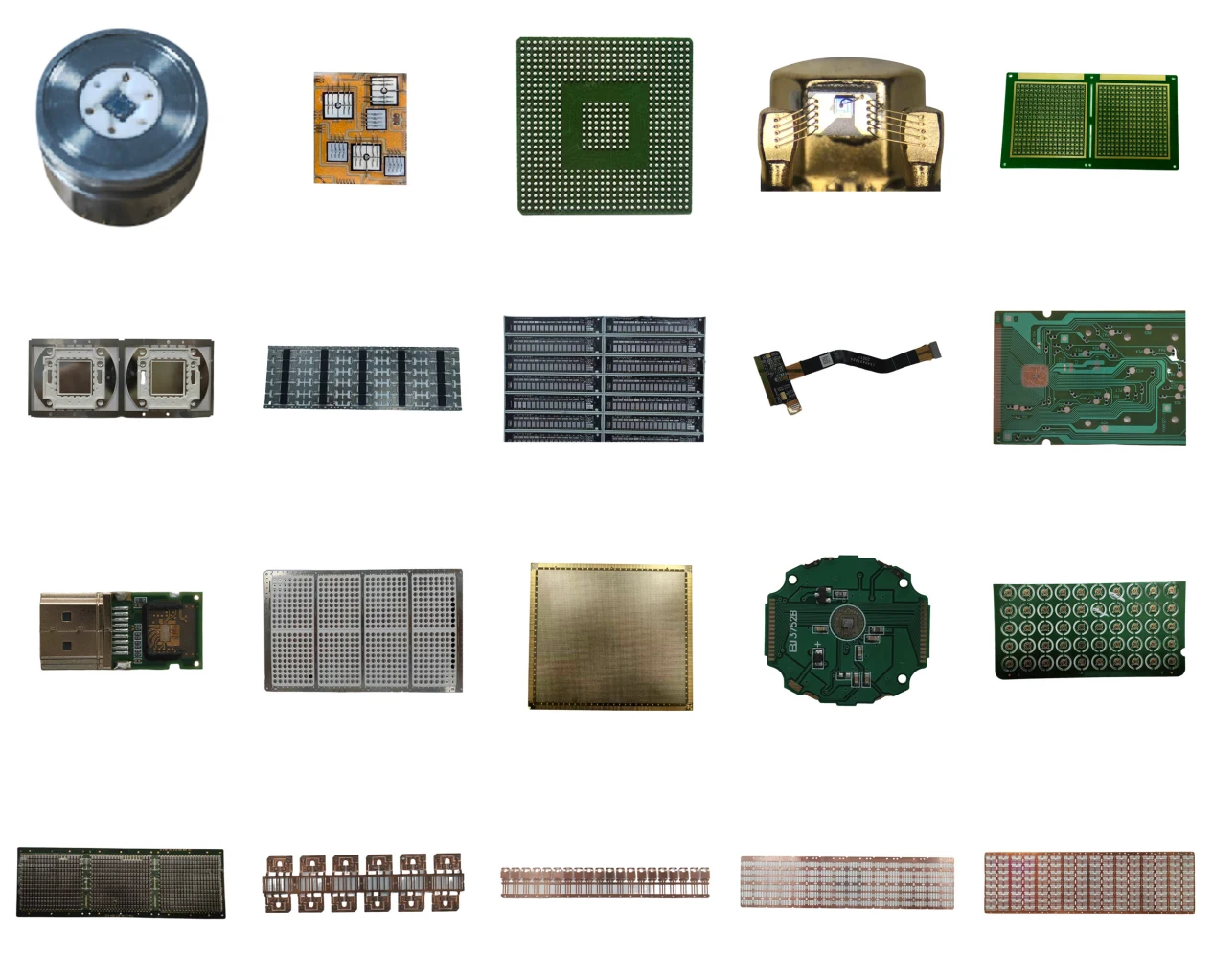

Testing Sample

Reviews

There are no reviews yet.