Category: Mechanical Equipment & Tool Parts

Mechanical Equipment & Tool Parts

Showing 241–256 of 377 results

-

MA-(3~12MM)×1800MM Steel Coil Slitting Production Line includes: uncoiler, guiding device, uncoiling tension device, coil head shearing

-

This design not only effectively resists collisions, falls, and other situations that may be encountered in the complex environment of automotive repair workshops

-

Top Quality Eyelash Extensions Tweezers

-

Top Quality Eyelash Extensions Tweezers

-

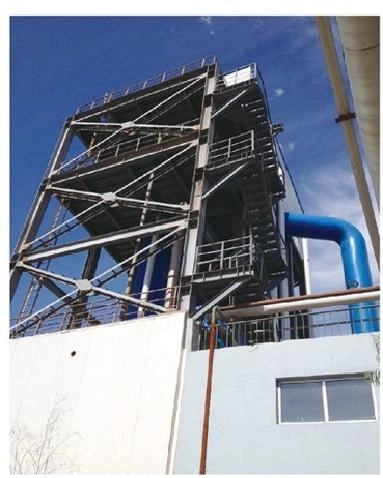

Pyrolysis furnace can be categorized into fixed and continuous types, with the former designed for one-time feeding and the latter for continuous feeding. Within the category of continuous pyrolysis furnace, there are two subtypes: grate rotation and double rotation of grate and furnace body structures.

-

Sectional structure without any bolt;Nice appearance with simple structure;Easy to install & disassemble;Pitch in 50mm to be and finish baking to pre-rust.

-

The coating has excellent electrical conductivity and thermal conductivity, which can be used as a coating for various electrical contacts.

-

-

Motor endurance cycle test bench, model: ZYDJ-9600 series, is loaded by an eddy current dynamometer

Control principle, customized test system to realize motor endurance cycle test. -

The MS324 handle lock from Shengjiu is a high-performance, industrial-grade rotating handle lock designed for use in electrical cabinets, communication devices, and automation control panels.

-

The multi-functional cutting machine is a highly integrated digital cutting device in modern manufacturing. It is no longer confined to cutting a single material. Instead, by changing different tool heads and processing software, it can achieve precise, efficient and automated cutting, drawing, engraving and other operations on various soft and hard boards. It is one of the core equipment for small-batch, multi-variety flexible production.

-

MVR Evaporation plant delivers substantial operational cost saving in areas with an ample supply of low-cost electrical energy.

-

Designed with consistent dimensions, excellent electrical conductivity, and high corrosion resistance, these pins are ideal for a wide range of connector systems, circuit assemblies, and power modules

-

Designed with consistent dimensions, excellent electrical conductivity, and high corrosion resistance, these pins are ideal for a wide range of connector systems, circuit assemblies, and power modules

-

Designed with consistent dimensions, excellent electrical conductivity, and high corrosion resistance, these pins are ideal for a wide range of connector systems, circuit assemblies, and power modules

-

Designed with consistent dimensions, excellent electrical conductivity, and high corrosion resistance, these pins are ideal for a wide range of connector systems, circuit assemblies, and power modules