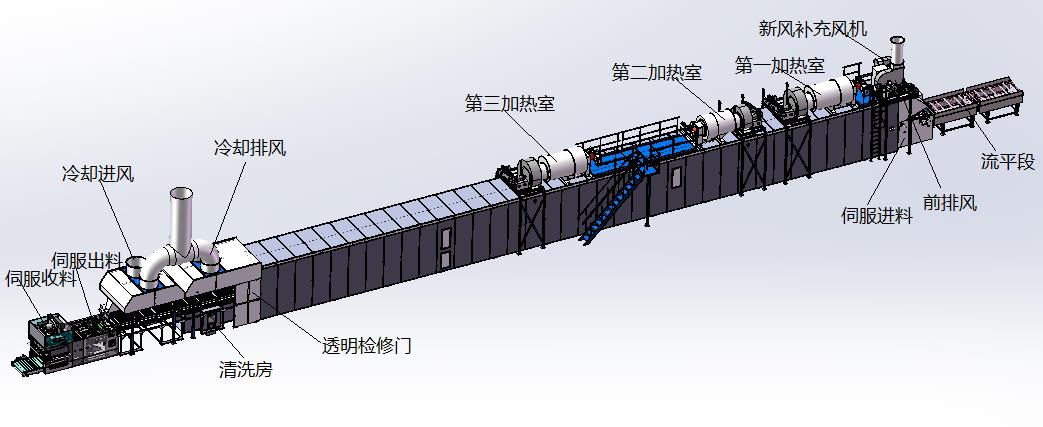

Metal sheet drying oven for can making

The oven is mainly used to dry the coating on the tin (or aluminum) sheet in the can making process. The entire line mainly consists of conveying, feeding devices, drying, cooling, and material collection and stacking.

Technical parameters of oven:

|

Applicable to metal sheet specifications |

Maximum |

1000×1250(mm) |

|

Minimum |

510×710(mm) |

|

|

Steel plate thickness |

0.14-0.50(mm)tin plate 0.17-0.50(mm)aluminum plate |

|

|

Sheet shape |

rectangular or corrugated iron |

|

|

Maximum weight |

2.6kg |

|

|

Maximum drying temperature |

230°C士2°C |

|

|

Standard drying temperature |

160-210°C |

|

|

Maximum production speed |

The total drying time corresponding to the running speed of 24M/2C drying room is 3,100 pieces/hour @10. Minutes |

|

|

The total drying time corresponding to the running speed of 30M/2C drying room is 4,500 pieces/hour @10. Minutes |

||

|

The total drying time corresponding to the running speed of 36M/3C drying room is 6,000 pieces/hour @10. Minutes |

||

|

The total drying time corresponding to the running speed of 39M/3C drving room is 6,700 pieces/hour @10. Minutes |

||

|

Maximum solvent volatilization |

72Kg/h |

|

|

Fuel type |

natural gas/LPG |

|

|

Number of heating systems |

2-3 sets |

|

|

Maximum consumption |

100m3/h |

|

Advantages of PLM new oven

Description of drying oven panel

1. The U-shaped inlaid wall panel link is adopted to eliminate the heat loss

of high temperature wind running out in the oven

2. The broken heat treatment process of inner wall plate and diameter plate

reduces the heat transfer coefficient of steel plate

3. The normal temperature of the outer body of the oven is + 5℃

Description of drying oven front exhaust

1. According to the EU EN1539 standard, the maximum amount of exhaust solvent

control is 10 g/m3.

2. Set the pressure sensor in the solvent volatile area, and automatically

adjust the exhaust air volume according to the change of gas concentration, so

as to reduce the loss of hot air on the premise of ensuring the minimum safe air

volume.

3. Suppose that the solvent emitting the gas is 45kg / h, and the exhaust

volume = 45/0.01=4500Nm3/h

4. Under the maximum solvent capacity of 75kg / h, the installed air volume

is automatically adjusted by 50008000 N m3/h.

Description of drying oven wicket

According to the specifications of the printed and coated products, a large number of C-shaped buckles and rollers (made of specialized food grade imported materials) are installed on the inner bracket and edge ears of the furnace frame, allowing the sheet (aluminum plate) to dry and run in a separate state from the furnace frame, effectively avoiding the problem of dot shaped scratches and burns in the printed and coated products.

1.LONGLI patent ¢ 10*2 tubular wicket with strong rigidity, high flatness,

light weight.

2. The two sides of the upper ear are changed to realize the suspension of

the coating products on the stove rack and reduce the chance of abrasion and

scald

3. Total weight of 36M oven rack: 1.68kg / 3650 =6132kg.

4. 20—200℃ Thermal energy consumption under drying conditions: 15 m3/h

(natural gas)

Description of drying oven heating room

1 Use the organized oxygen gas in the coating room to supplement to the two

combustion chambers 1500 Nm 32500 N m3/h to do fresh air supply to ensure the

oxygen content of the drying furnace.

2. Improve the working environment of the machine room and reduce the

expensive waste gas treatment cost:

3. The solvent in the gas also uses the fuel in the incineration cavity to

save the amount of gas.

4. Adopt internal standard 30:1 burner temperature control accuracy ± 1℃,

energy saving.

5. The circulating fan is controlled by frequency conversion control, and the

air volume is adjusted according to the product process requirements to save the

operating power of 8.2 kW / h:

Description of drying oven chain, the track

Chain and track are the key components of high-speed operation, and its

quality requirements determine the technical content of the oven operation.

Longli has completed this technical breakthrough after 2 years of technical

development

1. The oven special chain developed by LONGLI basically reaches the LTG

quality standard with high-speed operating conditions of 7000 pieces / h after

fatigue test.

2. Long service life of the chain and reduce the maintenance cost.

3. Moderate frequency quenching of rail surface, hardness HRC: 55℃, depth of

5mm.

4. Long service life of track and reduce maintenance cost.

Description of drying oven servo feeder

1. The configuration of high-precision rotation mechanism and material

treatment process is the basic condition for high-speed operation, and meets the

continuous operation condition of 7200 pieces / h.

2. Adopt vacuum adsorption positioning transportation, servo using the

international first-class brand to reach 150 times / minute, iron plate

positioning accuracy, stable operation, basically eliminate the probability of

abrasion.

3. The oven feed conveying adopts the hollow circular belt conveying

structure

Description of drying oven wicket

1. The steelness and flatness of the wicket are the key components of more

than 100 pieces / minute. LONGLI wicket has been confirmed by practical use in

this field

2. The resistance strength of the furnace is 470 Mpa

3. Electroplating adopts three nickel and one chromium process, coating

thickness 16um and potential difference 120MA

The chain lubrication station

PLM-oven chain oil injection lubrication system-composition introduction

Operational principle:

The oil injection system is automatically controlled by PLC. When the flower

rack sprocket rotates one tooth, the sensor will transmit the signal to the PLC,

give the signal to the oil injection machine solenoid valve through the PLC

feedback signal, and automatically lubricate the flower rack chain through the

action of the solenoid valve.

Reviews

There are no reviews yet.